Carl Thompson’s Custom Basses

by Tom Mulhern

Guitar Player Magazine

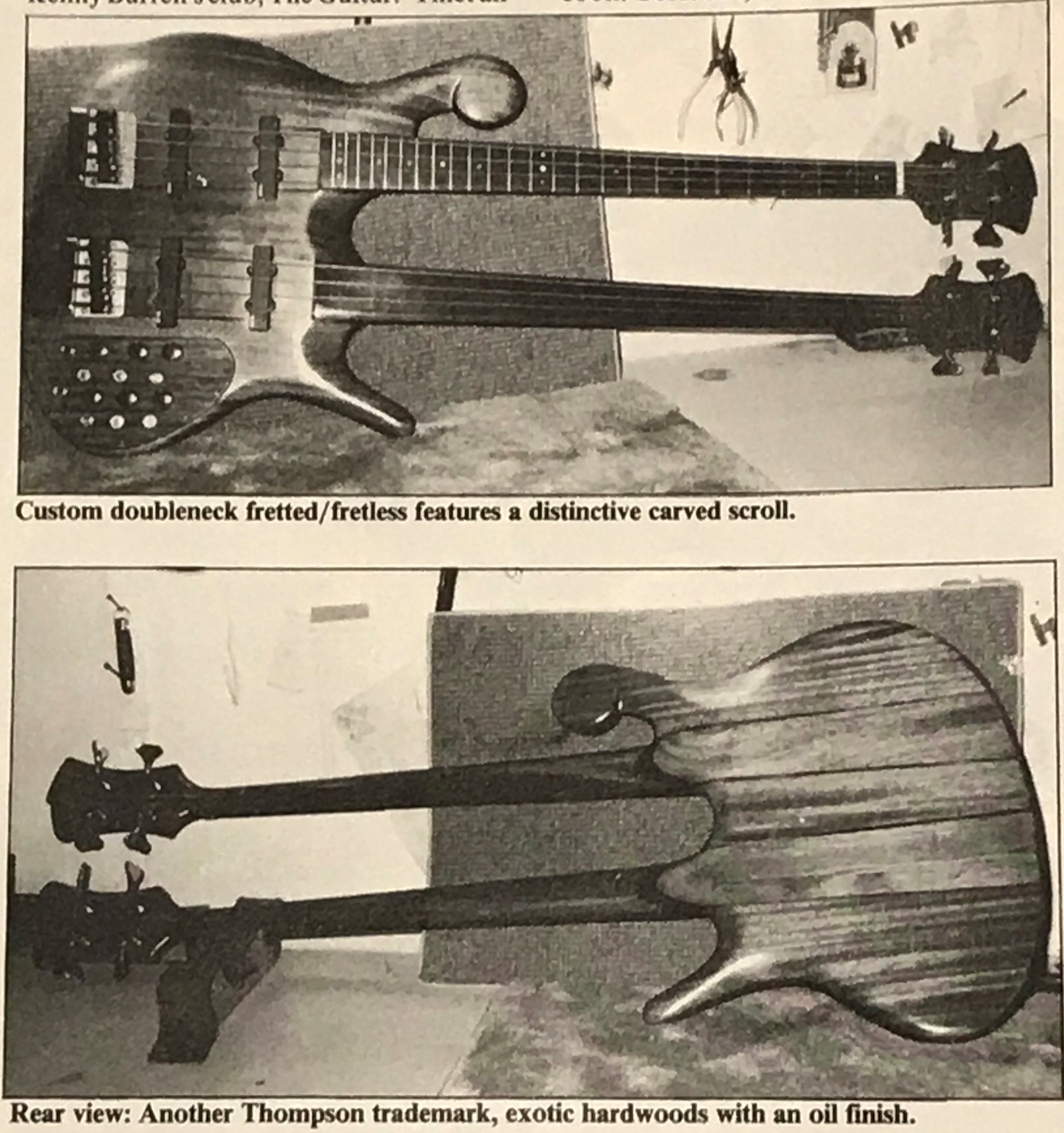

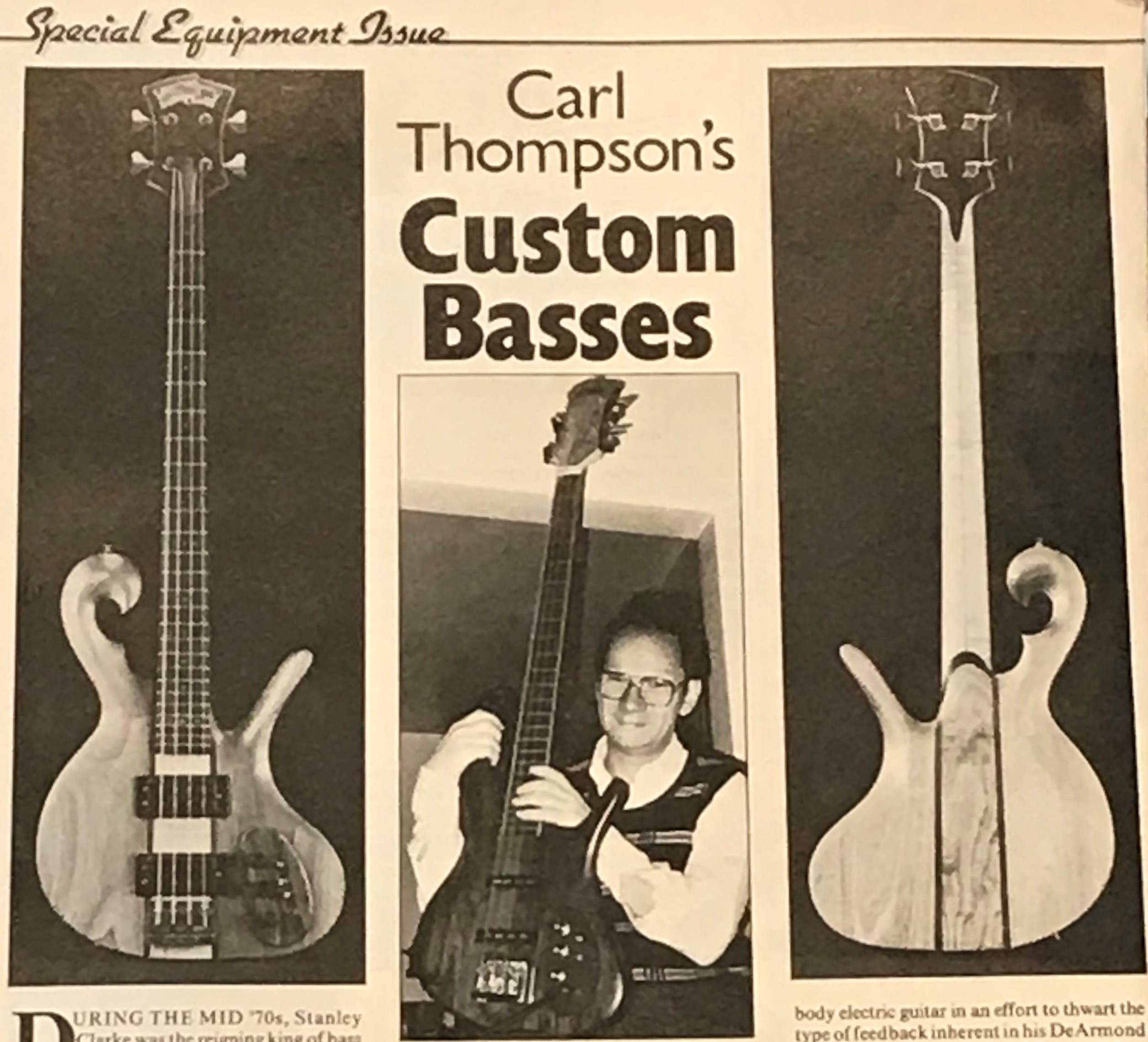

Above: Carl Thompson with black walnut 8-string bass flanked by two views of a stunning 26 fret 4-string with a mahogany body, a maple neck and two Schaller pickups. Note ebony “half moon” insert at the neck/body joint and distinctive sculpted horns.

During the mid 70’s, Stanley Clarke was the reigning king of bass guitar, and one of his showstoppers was a high-pitched soloing instrument, a piccolo bass, which looked like a bass but sounded very different (it was tuned an octave higher than a standard bass). Stanley’s unusual 4-string was the work of New York luthier Carl Thompson, a specialist in customer instruments ranging from a straight-ahead 4-strings to exotic fretless and double-neck models-and even some electric guitars. Today, 45-year-old Thompson still builds his basses by hand. They feature ornate scrolls on the body and ebony heel caps-trademarks of his craftsmanship.

Thompson has constructed instruments for many of new York’s top jazz and studio bassists, as well as musicians around the country-Bob Cranshaw, Rick Laird, Russell George, Ben Brown, Ken Smith, Michael Howell, Anthony Jackson, Chris Brubeck, Gene Perla, Dave Moore, Craig Nelson, Herb Mickman, and Billy Christ, to name a few. He also specializes in repairs and modifications at his shop (Carl Thompson Guitars, 171 Court St., Brooklyn NY 11201), fixing and fine-tuning the instruments of many of the city’s top guitarists and bassists. He also sells his own brand of bass string.

Despite his expertise, Carl didn’t always want to build basses. In fact, he was intent upon a career as a jazz guitarist. Growing up in a large musical family in Pitcairn, Pennsylvania (about 20 miles east of Pittsburgh), he learned guitar as a kid. His father, an inveterate tinkerer, played guitar and taught Carl some of the rudiments. Carl’s father had a machine shop in the basement and also specialized in carpentry and electronics, leading him in 1937 or ’38 to build a solid body electric guitar in an effort to thwart the type of feedback inherent in his DeArmond pickup-equipped arch-top Gibson. “When the solidbody Fender and Gibson Les Paul came out, it wasn’t really news to me, ” Carl explains. “My father’s solidbody had been around the house for years. He also built an electric bass in 1942 or ’43, and he even built some recording mechanisms. It’s funny that because the pickup hummed, he reversed one of the coils and produced a humbucker.”

Although he wasn’t taught wordworking or machining skills by her father, Carl feels that he absorbed some of that craftsman’s spirit: “My dad passed away about 10 years ago, but he still lives here at my bench-‘Don’t use that file, I told you. See! You used that file and you blew it’.”

Carl was persuaded to move to New York in the late ’60’s by a hometown friend, Russell George, a jazz and session bassist who worked with trumpeter Dizzy Gillespie, among others. Russell prompted Carl to take a job at designer/guitarist/retailer Dan Armstrong’s shop. “I thought I was going to be the world’s greatest jazz guitar player,” Carl says. ” Everybody thinks that. I got to New York, though, and walked into a wall of them.”

In the early ’70’s, Carl played in duos at Kenny Burrell’s club, The Guitar. “I met all the right people through Dan Armstrong’s guitar shop, too,” he says. ” Eddie Diehl worked there, and I learned most of the stuff by watching him do things like file frets. Eventually, Dan Armstrong closed up shop, and that’s when I started doing it on my own.”

Carl went into business with Joel Frutkin (after six years as Thompson’s partner, Joel left to pursue a career in teaching), and opened a shop in midtown Manhattan. They were extremely busy with studio players coming and going: “Make this nut, make that, adjust my bridge,” Carl reminisces. “It was moving too fast. I wasn’t a very good businessman then, and I got tired of fixing all those instruments. I thought maybe I could make an instrument myself. Joel and I got some money, bought some wood, and started putting basses together in 1974. Russell George spread the word around about me, because he got one of the first ones.”

Carl found that he prefers working alone, and says, “The shop in midtown Manhattan showed me that that was not the life for me. Those years there were good for me because I think I built whatever reputation I have, but I don’t think I could stand that kind of pressure again. It’s also hard to get anything done with everyone coming in and needing something yesterday all the time. But I think that’s where you learn. It’s like being a short-order cook: Get it out, and see what you can do. You make so many mistakes that you just have to learn.”

Always striving to improve his instruments, Carl recalls that his first bass was pure terror. “I didn’t have woodworking chops of any kind,” he admits. “I never really studied it. It just came to me. I think it’s a desire: If you put your head into it and you have any kind of talent for it, you’ll be able to do it.”

On his first bass, he accidentally hit upon what would later become a trademark of sorts. He was having difficulty fitting a neck into the mortise in the body and discovered a lot of leftover space in that hole. He then pondered how to cover the gap: “I figured I could add a piece of maple to the neck and start over with a fresh hole, but I thought it might look like I was trying to cover up something. So I tried a piece of ebony and put in on like a heelblock, and carved it so the neck flowed right into the body. It serves two purposes. First, it enhances the beauty of the instrument. Second, we can easily change the angle of the neck to the body by increasing or decreasing the taper of the block.”

Early on, Thompson decided to build his instruments of exotic hardwoods, and today he used maple, mahogany, walnut, or cherry for the neck depending on the customer’s choice and availability. Fingerboards are usually ebony, although rosewood is sometimes used, again depending on the customer’s desires. Nuts are made of ebony or other hardwoods, brass, or bone. Body woods include maple, mahogany, walnut, zebrawood, and cherry; these are sometimes trimmed with strips of padauk, rosewood, ebony, bubinga, or other exotics. “We even made a body once by combining pieces of wood that were cutoffs from other instruments,” Carl says. “We squared up some odds and ends and put them together in butcherblock fashion. The end result was excellent, and it became what we called the rainbow guitar.”

Among the unusual features on some of his first basses were 29-fret fingerboards. Carl had long pieces of ebony and thought he’d see just how many frets he could fit onto one board. “I don’t think that it would be practical to use a 29-fret fingerboard today because of all the popping and slapping,” he says. “I usually go for just 24 frets now.”

Carl credits the idea for the piccolo bass to Stanley Clarke, who came to him in 1974 asking for a bass-like instrument tuned an octave higher. “I thought I had to do a lot of different things to make a piccolo bass,” he recalls, “but in reality, it was mainly the strings that made the difference. I thought I might have to pull the headstock back to reduce tension in the strings. I had all these theories, and I was making it harder than it actually was. We started working on it, and I talked to John D’Addario, Sr., a wonderful man, about strings. He really helped me a lot in those days. He always sent me samples to try, and I had a direct line to a lot of professional players. We still work together, and the D’Addario company still make strings for me.”

Stanley wanted his piccolo bass fretless, but without frets, the sound was weak, leading Carl to eventually add them. A few years after building the first piccolo, Thompson constructed another for Clarke, this time with a thinner neck and its scale reduced from 34′ to 32′. Since then, he has built a few more piccolo basses, primarily for studio musicians such as Nashville’s Craig Nelson, who has also purchased a fretted/fretless doubleneck standard bass from him.

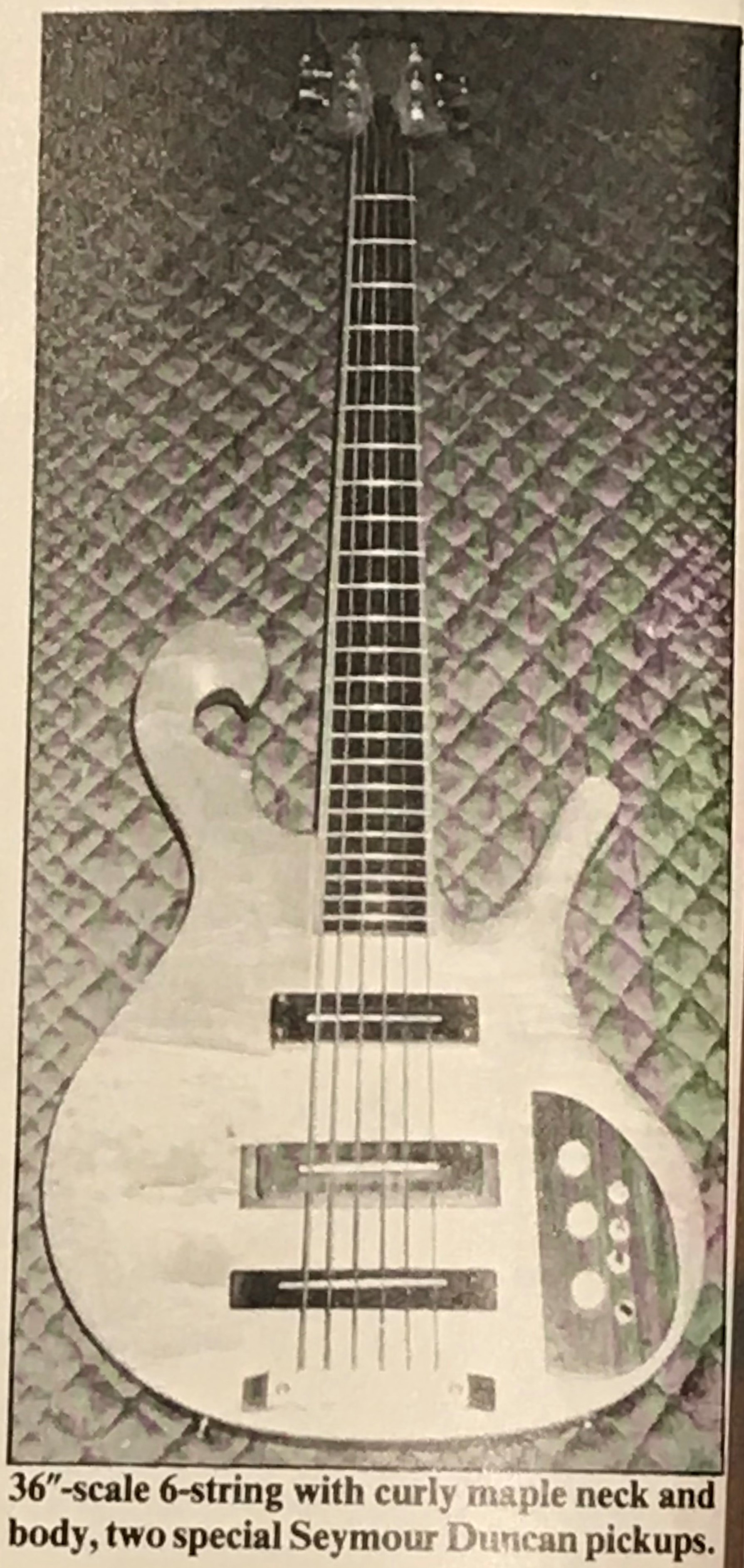

During his formative years as a luthier, Carl built a lot of unusual basses (developing a reputation for them along the way), including a 6-string for Anthony Jackson. His biggest problem was obtaining pickups because there were few companies specializing in custom units, which were needed in order to accommodate the wide string spacing. On the early 6-strings, he used a couple of Emmons steel guitar models that were essentially extra-wide standard guitar pickups. He made wooden covers and mounted the pickups in wood. He states, “The sound wasn’t perfect-obviously they were intended as guitar pickups-but they worked okay. Anthony understood their limitations.” Carl later built a fretless 6-string for Chris Brubeck, again with “make-do” pickups. Because the market for custom pickups has improved, Carl believes that his current basses are far superior, and says, “I’d like to put new pickups in those old basses to get their true sound.” Recently, Carl built a 36″-scale 6-string for a studio player named Dave Moore, employing Seymour Duncan custom pickups with bar polepieces. Thompson uses a 34″ scale for most basses, but he feels that the longer scale improves the intonation and enhances the overall sound, especially in the lower registers.

Thompson gives a lot of credit to Michael Parisi, who carves all of Carl’s basses today; Carl does the assembling, wiring, and finishing. Every aspect is done by hand, except for bandsawing the rough body shape and tablesawing the neck joint. “Every instrument is truly an individual,” Carl says. “I always think of every instrument as my first time. It’s kind of like playing the guitar, because I was never the kind of player who was good in a studio situation. Making something the same every time or playing the same way just wasn’t my way of doing things.” Since they are worked by hand, each of the fingerboards is slightly different, and Carl says, “We try to keep the arch of the fingerboard slight because due to the nature of today’s styles-with everybody popping, slapping and so forth-we are able to maintain a relatively low action without the notes choking.”

All Carl Thompson basses have natural oil finishes. The luthier likes oil because it lets him work it in with his hands. “When lacquer chips,” he adds, “you have to strip it down and try to match the color. It’s hard to keep up. If you use good oil, anyone can take care of it. If you get a nick, take some fine sandpaper and work it out. Then reoil it, and it’s back where it was. I think the neck feels better, and most of the guys I deal with like the natural feel of the wood.”

Besides building and servicing basses, Carl also enjoys teaching guitar and showing others how to take care of frets and make adjustments on their instruments. “Teaching gives me a chance to learn as I go,” he proclaims. “I teach a course in what I call ‘keeping your instrument alive.’ It’s for musicians who want to line up bridges, keep frets in condition, adjust necks, and so forth-all those functional things. I teach at my apartment, which is also my shop for final work-all the carving and heavy-duty work is done in New Rochelle at Mike Parisi’s. Playing, teaching, building-I look at them as one thing. I like to do them all, and try to do them the best that I can.”

Becoming a millionaire isn’t Carl’s objective. He enjoys his work, and he tries to treat all his customers fairly (“I give an estimate on an instrument before I start building, and then I charge what the materials and my time are worth-no more”). Many first-time customers expect a big plant or workshop, but it’s all in his apartment, and he greets everyone congenially: “My door’s always open, and people come in and out of here’ the refrigerator’s always stocked if they want something to drink or a sandwich. They can sit in the living room and watch MTV or listen to records. I’m in the city, but I’m a country boy, and that’s the way I like it.”

Carl Thompson is grateful for his customers’ faith, and he feels that he has carved a niche in the bass building world. “Somehow when I was starting out,” he says, “I got a reputation for building unusual basses. The guys who wanted them had more faith in me than I had in myself. I’m glad and thankful they did.”

Leave a Reply

You must be logged in to post a comment.